Let’s talk about the maintainability of an adult tricycle, what it encountered and whether it is possible to repair a bicycle with a differential at all

The epic with one of our bikes lasted for several months and it all happened with some difficulties. I would like to share the experience I gained in trying to repair the bike. Let’s get straight to the point.

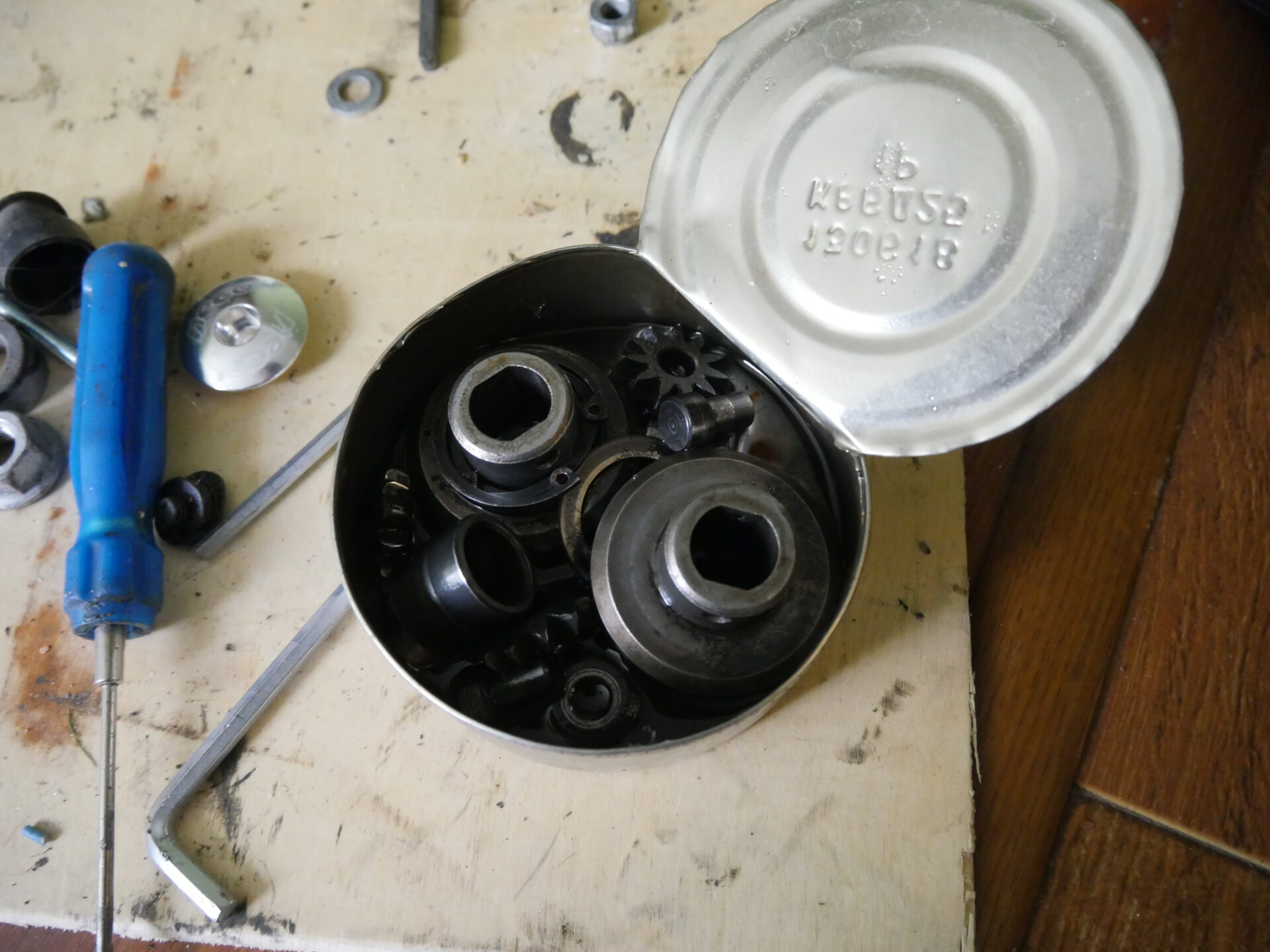

Differential

Three-wheeled bicycles have, in essence, two types of construction – in the first, the drive goes to one wheel, and the second spins like some dummy wheel, from which nothing in the movement depends, in the second there is a full-fledged differential behind the bicycle, which allows you to rotate two rear wheels simultaneously. I was unable to disassemble it before (I could not remove one of the axles of the bicycle), so for the two years that we had the bicycle and for another ten years before our use, no one climbed into this part of the bicycle. To make it clear what we are talking about, here is a video from the moment of its disassembly:

The video shows the design and the main reason for the disassembly – thickening grease, which turned into some kind of swampy mixture. In a burning desire to bring the differential to its senses, I started looking for greases that could be suitable for it. The grease was chosen from the Castrol brand, namely Castrol LMX . This grease is often used by modelers (people who drive mini-model cars that also have a differential and quite serious loads on it), so I saw no reason why it wouldn’t be suitable for me. Initially, the idea was that any graphite-based grease would be a good option, but after reading the reviews, I came to the conclusion that it can only ruin the mechanism. Castrol is based on classic lithol with additives that positively affect the operating parameters of the grease. And although the grease is quite expensive, changing the mechanism itself will be much more expensive (more on this below).

For quite a long time, the differential lay there waiting for its time, and when I started cleaning it, it turned out that despite the presence of old grease, some of its parts were still corroded and needed to be cleaned of rust.

For quite a long time, the differential lay there waiting for its time, and when I started cleaning it, it turned out that despite the presence of old grease, some of its parts were still corroded and needed to be cleaned of rust.

For this purpose, a suitable liquid was used, with the help of which the spare parts became like new.

For this purpose, a suitable liquid was used, with the help of which the spare parts became like new.

During service, a chip formed on one of the gears. The chip is insignificant and does not cover the main part of the working surface, so it is unlikely to interfere with high-quality work. I had more questions about the bearings.

During service, a chip formed on one of the gears. The chip is insignificant and does not cover the main part of the working surface, so it is unlikely to interfere with high-quality work. I had more questions about the bearings.

I searched for their model experimentally. The fact is that (to my surprise) some stores have the same differential as mine for sale.

It is googled, respectively, as “Differential für Pfautec-Dreirad” and is sold, mainly, in Germany . At this link there are tabs “MONTAGEANLEITUNG 1” and “MONTAGEANLEITUNG 2”, where there are photos of the differential and its description. To this data not to be lost on the Internet, I uploaded them to the site trike_differential_1 and trike_differential_2 . By the name I found it on eBay complete with bearings.

It is googled, respectively, as “Differential für Pfautec-Dreirad” and is sold, mainly, in Germany . At this link there are tabs “MONTAGEANLEITUNG 1” and “MONTAGEANLEITUNG 2”, where there are photos of the differential and its description. To this data not to be lost on the Internet, I uploaded them to the site trike_differential_1 and trike_differential_2 . By the name I found it on eBay complete with bearings.

SKF bearings, model 6003-2RSH . The fact is that these bearings were difficult to find anywhere locally, I had to order them online. They have slightly non-standard sizes, so it is advisable to take the same ones. Each costs about 4 USD. In theory, you can take cheaper ones with the same parameters for 1 USD, but here the master is already the boss, and I took those that are guaranteed to fit. In addition, the chassis of the bicycle is not the place where you should save on bearings.

SKF bearings, model 6003-2RSH . The fact is that these bearings were difficult to find anywhere locally, I had to order them online. They have slightly non-standard sizes, so it is advisable to take the same ones. Each costs about 4 USD. In theory, you can take cheaper ones with the same parameters for 1 USD, but here the master is already the boss, and I took those that are guaranteed to fit. In addition, the chassis of the bicycle is not the place where you should save on bearings.

As you can see, the cost of the differential itself is about a third of the cost of a bicycle on our market, so it is better to service it in a timely manner than to replace it. Things were a little more complicated with the rear axle, of which we have two.

Most likely, this axle is impossible to find, so you need to treat it with care, especially the thread. Surprisingly, no rust was found on the axle, and still I decided to seek help from a locksmith who turned two spare axles. If you plan to use your bike for a long time – I recommend doing the same. In extreme cases, if something suddenly happens to your axle and you need dimensions – write in the comments, I will try to help with the exact dimensions of all the main diameters.

Most likely, this axle is impossible to find, so you need to treat it with care, especially the thread. Surprisingly, no rust was found on the axle, and still I decided to seek help from a locksmith who turned two spare axles. If you plan to use your bike for a long time – I recommend doing the same. In extreme cases, if something suddenly happens to your axle and you need dimensions – write in the comments, I will try to help with the exact dimensions of all the main diameters.

It is difficult to say how the differential will behave in the future, since the load on the electric bike is somewhat higher than during normal use, but during two years of use there have been no defects. As for the chip on one of the gears, which I wrote about above, the chip is most likely due to wear from long-term use, or they accidentally hit a pothole and there was a blow, which caused the chip. In any case, the design of the differential and the rear axle are completely functional and serviced.

The article was written when the bike was already running and we had managed to ride it for about 50-70 km. Let’s move on.

Bottom bracket and connecting rod

I will write about this site in general, since there were no fewer problems with it.

The frame is steel, so disassembling the bottom bracket was a breeze. Plus my crooked hands, which started twisting in the wrong direction, and rust. A lot of rust.

The frame is steel, so disassembling the bottom bracket was a breeze. Plus my crooked hands, which started twisting in the wrong direction, and rust. A lot of rust.

Despite, or rather even because of, the fact that the nut was plastic, moisture was getting into the bottom bracket very actively. The rust was such that the plastic had to be sawed off and broken off to somehow remove it.

Despite, or rather even because of, the fact that the nut was plastic, moisture was getting into the bottom bracket very actively. The rust was such that the plastic had to be sawed off and broken off to somehow remove it.

The experience was not a pleasant one, and the thread had to be washed with the same rust remover as the parts of the differential, but later the thread became clean and it could be used for a new bottom bracket. Here I was in for a surprise – having bought a bottom bracket comparable in size to the one that was in the original (the original had a non-name, if I’m not mistaken), the chain line, or chain line in the people, turned out to be incorrect due to the fact that in addition to the bottom bracket, the crank was also changed. In the classic layout, as I understand it, the bike had a crank for planetary/road bikes, and I installed the one that was from mountain bikes (Prowheel Zephyr).

The experience was not a pleasant one, and the thread had to be washed with the same rust remover as the parts of the differential, but later the thread became clean and it could be used for a new bottom bracket. Here I was in for a surprise – having bought a bottom bracket comparable in size to the one that was in the original (the original had a non-name, if I’m not mistaken), the chain line, or chain line in the people, turned out to be incorrect due to the fact that in addition to the bottom bracket, the crank was also changed. In the classic layout, as I understand it, the bike had a crank for planetary/road bikes, and I installed the one that was from mountain bikes (Prowheel Zephyr).

This responded to me with a difference between the planetary sprocket and the crank sprocket of 0.7-1 cm, which is a lot. Therefore, I had to take a narrower bottom bracket than my own. The dimensions of my own bottom bracket were 68×127, and the one that was installed was 68×121 or even 117 (I don’t remember exactly, because I took two, I installed the one that was 117). This evened out our chain misalignment and allowed me to use a crank on which, if desired, you can easily change the sprocket to a larger or smaller side.

This responded to me with a difference between the planetary sprocket and the crank sprocket of 0.7-1 cm, which is a lot. Therefore, I had to take a narrower bottom bracket than my own. The dimensions of my own bottom bracket were 68×127, and the one that was installed was 68×121 or even 117 (I don’t remember exactly, because I took two, I installed the one that was 117). This evened out our chain misalignment and allowed me to use a crank on which, if desired, you can easily change the sprocket to a larger or smaller side.

The original crank had a 33-tooth sprocket. The purchased crank was equipped with a 36-tooth sprocket, but in my opinion this turned out to be a lot and it was decided to replace the sprocket with a Spelli SCR-34T-ST . Why did you need to change the sprocket? The fact is that even when riding without a motor, gears 1-2 were very, very easy to scroll, which made them essentially pointless, because you still couldn’t really go up the mountain where you had to go up on gears 1-2 under your own power, and when riding with a motor, the original sprockets were about 3-4. To correct this imbalance in the direction of full use of all seven gears of the bicycle, it was decided to slightly increase the gear ratio. One link did not radically change anything, but the riding comfort increased.

The original crank had a 33-tooth sprocket. The purchased crank was equipped with a 36-tooth sprocket, but in my opinion this turned out to be a lot and it was decided to replace the sprocket with a Spelli SCR-34T-ST . Why did you need to change the sprocket? The fact is that even when riding without a motor, gears 1-2 were very, very easy to scroll, which made them essentially pointless, because you still couldn’t really go up the mountain where you had to go up on gears 1-2 under your own power, and when riding with a motor, the original sprockets were about 3-4. To correct this imbalance in the direction of full use of all seven gears of the bicycle, it was decided to slightly increase the gear ratio. One link did not radically change anything, but the riding comfort increased.

Planetary sleeve

The planetary hub was cleaned of dirt. I didn’t bother to get into the structure itself, because both experience and the price of this planetary gear on the secondary market tell me that while it works, let it work, and then it will be easier to change it to something fresh.

Some time before disassembling the bike, I had a strange incident – when I was going out onto the road and trying to turn the pedals – they got stuck and I couldn’t go. The situation was not pleasant, I had to go the whole way on the engine. I thought that something was wrong with the planetary gear. And I was right. Partly.

Some time before disassembling the bike, I had a strange incident – when I was going out onto the road and trying to turn the pedals – they got stuck and I couldn’t go. The situation was not pleasant, I had to go the whole way on the engine. I thought that something was wrong with the planetary gear. And I was right. Partly.

The planetary hub has a special washer that holds it in the axis in the frame mount. It holds the planetary in the correct position. All planetary gears have such washers and each has its own size. As you understand, looking for a washer for a planetary hub is difficult. Not advertising for, but I found the washers in one store. On the website where I bought it, the part was called “sram sachs t3-r5-s7 washer”. For comparison – here this washer costs about 1$, from Germany I could bring it for 6 euros + delivery. At first I wanted to install two washers instead of one, but the design did not allow and I resigned myself to the fact that one new one is better than nothing. These washers were bought a little just in case, so that they were always at hand. There were no problems with the planetarium itself, so I didn’t do anything with it.

The planetary hub has a special washer that holds it in the axis in the frame mount. It holds the planetary in the correct position. All planetary gears have such washers and each has its own size. As you understand, looking for a washer for a planetary hub is difficult. Not advertising for, but I found the washers in one store. On the website where I bought it, the part was called “sram sachs t3-r5-s7 washer”. For comparison – here this washer costs about 1$, from Germany I could bring it for 6 euros + delivery. At first I wanted to install two washers instead of one, but the design did not allow and I resigned myself to the fact that one new one is better than nothing. These washers were bought a little just in case, so that they were always at hand. There were no problems with the planetarium itself, so I didn’t do anything with it.

Fork

The fork of this tricycle is the part of it that made me want to bang my head against the wall. Why? Find a fork with a stem diameter of 1.1/8, threaded, with disc brake mounts, with a fork travel of 60-80 mm (now the standard is 100) and not at a price of 80-100 USD. To hell with it, with the stem diameter, the problem was that it was threaded. If you install a non-threaded one, the handlebars are too low for a road bike. With a fork with a travel of 100 mm, we have a distorted geometry, when even in the lowest saddle position the bike has too much clearance for its geometry and an uncomfortable fit. It is not a problem to find a threaded fork among the Chinese, but the quality of that under-aluminum for a 400W motor will be too lousy. I managed to buy 2 forks before I solved the issue with a strange but working method, Zoom with Avid BB5 brakes (the brakes there were only half the price and are already showing off on my Schwinn).

The fork was for disc brakes+V-brake, its “double crown” adjustment allowed me to easily choose the fork height that I needed, and the design, again, which involves the presence of two crowns, allowed me to fix it tightly in the frame with the crown itself. Yes, I know, you will say that “this is wrong”, “a different stem is needed for such a fork” – and you will be right, but in this particular case it was the only solution that allowed, on the one hand, to maintain a comfortable handlebar height, and on the other hand, to have a disc brake, which in the case of an electric bike is much more useful than a rim brake.

The fork was for disc brakes+V-brake, its “double crown” adjustment allowed me to easily choose the fork height that I needed, and the design, again, which involves the presence of two crowns, allowed me to fix it tightly in the frame with the crown itself. Yes, I know, you will say that “this is wrong”, “a different stem is needed for such a fork” – and you will be right, but in this particular case it was the only solution that allowed, on the one hand, to maintain a comfortable handlebar height, and on the other hand, to have a disc brake, which in the case of an electric bike is much more useful than a rim brake.

With such a fork, the bike acquired additional brutality. True, there were no fender mounts on the fork, but I solved this issue in my own way just the other day, and the bike is back in full gear. Wife says that it started to ride a little differently – more control on the one hand, but also greater fork stiffness on the other. It’s hard to say whether this is a plus or a minus, but the handling has become better and the bike has become more responsive.

Dyeing

The rust on the frame, which had been showing since the purchase, could not wait any longer.

It was decided to paint the frame at least from a spray can, so that the bike would have at least some protection. The paint was bought the most ordinary (at first, I, however, went astray and took paint for hot surfaces, but then I corrected myself when I realized that somehow it would not dry). The shade matched the native one, so I could paint without fear, because everything that would peel off would simply expose the native, glossier paint. Despite the cheapness of the paint, the coating turned out to be quite high-quality and good, and despite the nuances of reassembling the bike, it did not peel off or scratch anywhere. Of course, with a steel frame, the best option would have been to sandblast the entire frame, prime it and cover it with high-quality paint and varnish, but due to the lack of a compressor, this is impossible to do. Over time and if possible, all this will be done.

It was decided to paint the frame at least from a spray can, so that the bike would have at least some protection. The paint was bought the most ordinary (at first, I, however, went astray and took paint for hot surfaces, but then I corrected myself when I realized that somehow it would not dry). The shade matched the native one, so I could paint without fear, because everything that would peel off would simply expose the native, glossier paint. Despite the cheapness of the paint, the coating turned out to be quite high-quality and good, and despite the nuances of reassembling the bike, it did not peel off or scratch anywhere. Of course, with a steel frame, the best option would have been to sandblast the entire frame, prime it and cover it with high-quality paint and varnish, but due to the lack of a compressor, this is impossible to do. Over time and if possible, all this will be done.

As you can imagine, painting required a complete disassembly and reassembly of the bike. It was a first for me, and it was nerve-wracking to put everything back together correctly, but in the end, although the whole process took about 2-3 months, the bike was restored and back in action.

Other

One of the main ideas of all this was the desire to install disc brakes on the bike. And this was fully achieved. My favorite Avid BB7 was installed , with which the bike slowed down started a new life. The brakes work great, allowing you to stop the bike firmly in place if necessary. With its high weight, this is sometimes absolutely necessary, so it’s worth it.

In general, this can be called the first official overhaul of a tricycle.

In general, this can be called the first official overhaul of a tricycle.

Aftertaste

Today we understood a lot. Well, you are today, and I am in the process of implementing all this. If I were asked to state the main points, they would be:

- The carriage is not always replaced with the same one;

- Different cranks from different types of bikes can give different chain line;

- The steering column cannot be (by simple means) changed to another type and you have to work with what is there;

- The tricycle differential can be ordered separately, but the rear axles are impossible to find;

- It is advisable to service the carriage assembly in a timely manner to avoid rust;

- It is necessary to monitor the condition of the planetary sleeve washer so that it does not jam at an inopportune moment;

- Although the steel frame is more reliable, it requires timely maintenance.

The post turned out to be very long, but I initially thought it would be even longer. I might have missed some parts, so if you have any questions – ask, as a person who has already disassembled and completely assembled this bike, I can advise you on repair and maintenance within the limits of my knowledge 🙂

UPD

Interestingly, I found parts for this tricycle. This store has a certain variety of them.

In one of the stores, the differential was labeled as “Fahrrad Differential Achse Dreirad Biria Pfautec Kynast Mifa Schwarz 22 Zähne”, most of the words in this are probably the names of the brands under which bicycles with similar parts were produced.

Discover more from I become a Creature

Subscribe to get the latest posts sent to your email.